My garage is just one giant toy box. In 2009, I [with help from my wife and friends] used it to build a large 20 foot canoe for racing down the Missouri river. Since that race, the boat has hung from the ceiling of my garage in shame not seeing an ounce of water. I have also added a third boat, a Hobie Adventure kayak that is pedal powered. At some point, it becomes difficult to store all of the boats properly. Currently, I have two boats hanging from the ceiling and one on a wooden shelf that I made against the wall. When I add in the other assorted toys, and kid stuff, it becomes difficult to get access to the boats and they become neglected.

I built a manual pulley system for my first boat, “The Turd”, a 14 foot Mad River Adventure canoe. This system works great.

I purchased a bicycle pulley system for First Draft, a 20 foot home built carbon fiber canoe. This system is horrible and must be replaced!

Built a manual shelf to hold the 16 foot Hobie Adventure kayak. This has been perfect!

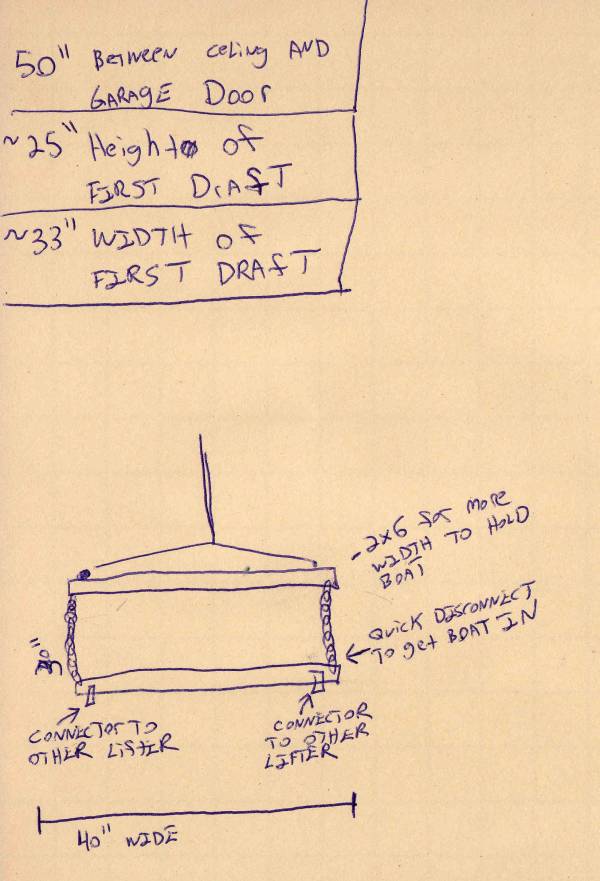

So after having an amazing weekend paddling as part of Colter’s Crew I realized I needed to get my boat back up and running again for speed, cause its fun to win! If I’m going to get the boat back to working order, I need to be able to get to the boat to work on it. This means that I need a pulley system that works. I explained to Henry “my father in law, not my lazy sleeping brother” what i wanted in the garage. Then we went inside to draw up plans. Henry is a mechanical engineer by trade, and I a computer engineer by trade started at opposite ends of the table. I ended up with the following drawing to show what I thought part of the hoist mechanism would look like.

Quite pleased with myself for taking measurements of the boat and knowing what I was getting into, I went to check on Henry’s progress. I was thoroughly embarrassed!

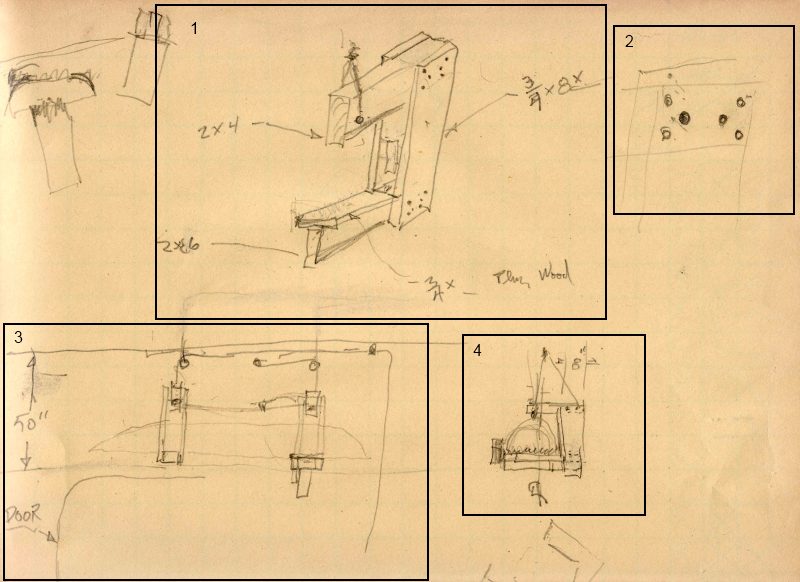

Henry’s diagram for the pulley system consisted of four separate sections with one in 3D. Lets go through them.

Section 1 and 4: This shows the mechanism that is the cradle of the boat. I explained that I wanted a top and bottom to hold the boat with the gunwales facing down and a top piece to keep the straps from pressing on the side of the boat. I wanted one of the sides to disconnect so it was easy to place the boat inside of the “circle” without having to go to the end of the boat. As the boat is 20 feet long, it nearly touches each end of my garage. Henry designed a C shape with one open side to save me the work. He patiently explained to me the value of the open side. He later drew section 4 to show how that section would hang slightly off center to force the boat to the side with closed section and keep it from falling off the form.

Section 2: This section is how we agreed to attach the side of the form together. Our final decision was two bolts through the middle and two screws on each side in an angle creating an X if you could see through it. This will become more clear as I create the piece and document it here.

Section 3: This is a side view of the garage with the rails for the garage door visible and where the canoe would hang.

I’m excited to implement this design and I hope that I do it justice as I go forth. Then I’ll have more access to the boats and can effectively use them all!

Hogan